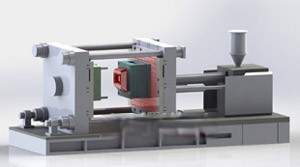

Working principle:

A very short pulse of current (1-4 seconds) activates the system and immobilizes the mold to the back of the machine without time limit, requiring no continuous electrical power or heat generation. The system is demagnetized and the die is removed by changing the direction of the magnetic force of the working permanent magnet by a different current pulse.

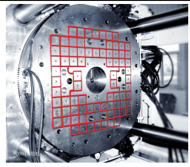

Safety performance of RUD rapid die change system

Each pole of the rapid mode change system is an independent magnetic area. The core of the steel and the 5 sides of the encircling high-energy permanent magnet (ALnico + ALnicO) ensure the concentration and persistence of the high strength magnetic force (MMF). Electronically controlled permanent magnet technology is inherently safe because the clamping force always comes from the magnetic field of the permanent magnetic material Each

The asymptotic sensor detects the contact state between the mold and the magnetic template in real time

FCS (Magnetic Flux Detection System) monitors actual magnetic force conditions

UCS (Magnetic Saturation Detection System) confirms that magnetic energy conversion is in place

Safety key to prevent misoperation and accidental demagnetization

Perfect clamping force

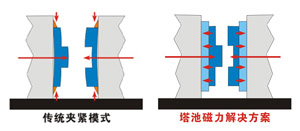

The traditional external compression mode causes the inevitable force deviation of the die, especially in the large die.

Due to the uniform distribution of clamping force on the contact surface, the mould will not be deformed by any heavy pressure. The perfect combination of mold, magnetic template and machine back plate improves product quality and repeatability.

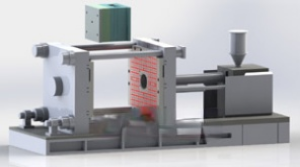

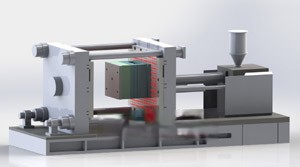

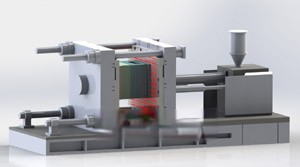

第一步:吊入模具

第二步:模具对准定位环

第三步:注塑机合模

第四步:充磁成功,注塑机开模